解决方案

Solution

Vision Test Solution

Location: 首页> Products> Vision Test Solution>

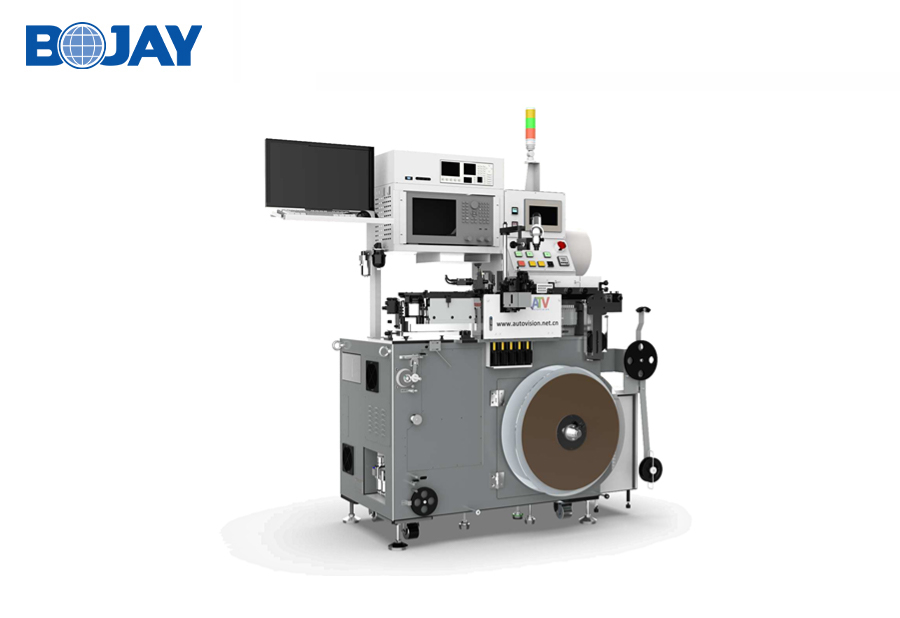

Testing and Package Equipment | ATV-X4800

Component testing sorting and packaging equipment based on AI vision algorithm detection

High Speed:5200pcs/min

Accurate:High precision mechanical and electrical design,Test module test accuracy up to 0.1%

Convenient:First equipped with AI algorithm in the industry

Simple and easy to operate without any parameter

Make sure no defects will be missed. as well as low false positive rate

- 产品详情

- 文件下载

Advantages

● High speed motor control, Independent research and development of the core driver of bootable disk, The processing speed can reach to 6000pcs/min

● Feeding at high speed, Vibrating bowl bought from DAISHIN, The feeding speed can reach to 6500pcs/min

● The motor works in a stable condition, The frequent start and stop and there is no jitter pulse output to ensure no damage to wearing parts

● The feeding system works in a stable speed, Speed flfluctuation: ±100pcs/min

● Low vulnerability, The dual motion detection of FPGA and motor drive. Provide extra safety protection for wearing parts and products

Key Specification

Test Precision | ≤0.1% |

AOI Test Precision | Max 6.9μm/pix |

Product Applicable Size | 0201-1206 British System |

Speed | Max 5200pcs/min |

System | ATV AI System |

Camera module | 3 high frame rates (Extensible) |

Temperature Control | 140-300℃±5℃ |

Mechanical & Electrical Specification

Inner Dimension | 1320(L) * 786(W) * 1820(H)mm |

Operation Door Dimension | 820(W) * 1670(H)mm |

Product Net Weight | approx. 240kg |

Gross Weight | approx. 280kg |

Air source pressure | 0.5~0.8MPa, 200L/min |

Power Consumption | 1.2KW |

Input Voltage | 220VAC 50Hz |

Positioner Control Interface | Touch screen |

Control Mode | PC&FPGA |